Examples are valid for:

TMflow Software version: All

TM Robot Hardware version: All

Other specific requirements: None

Note that older or newer software versions may have different results.

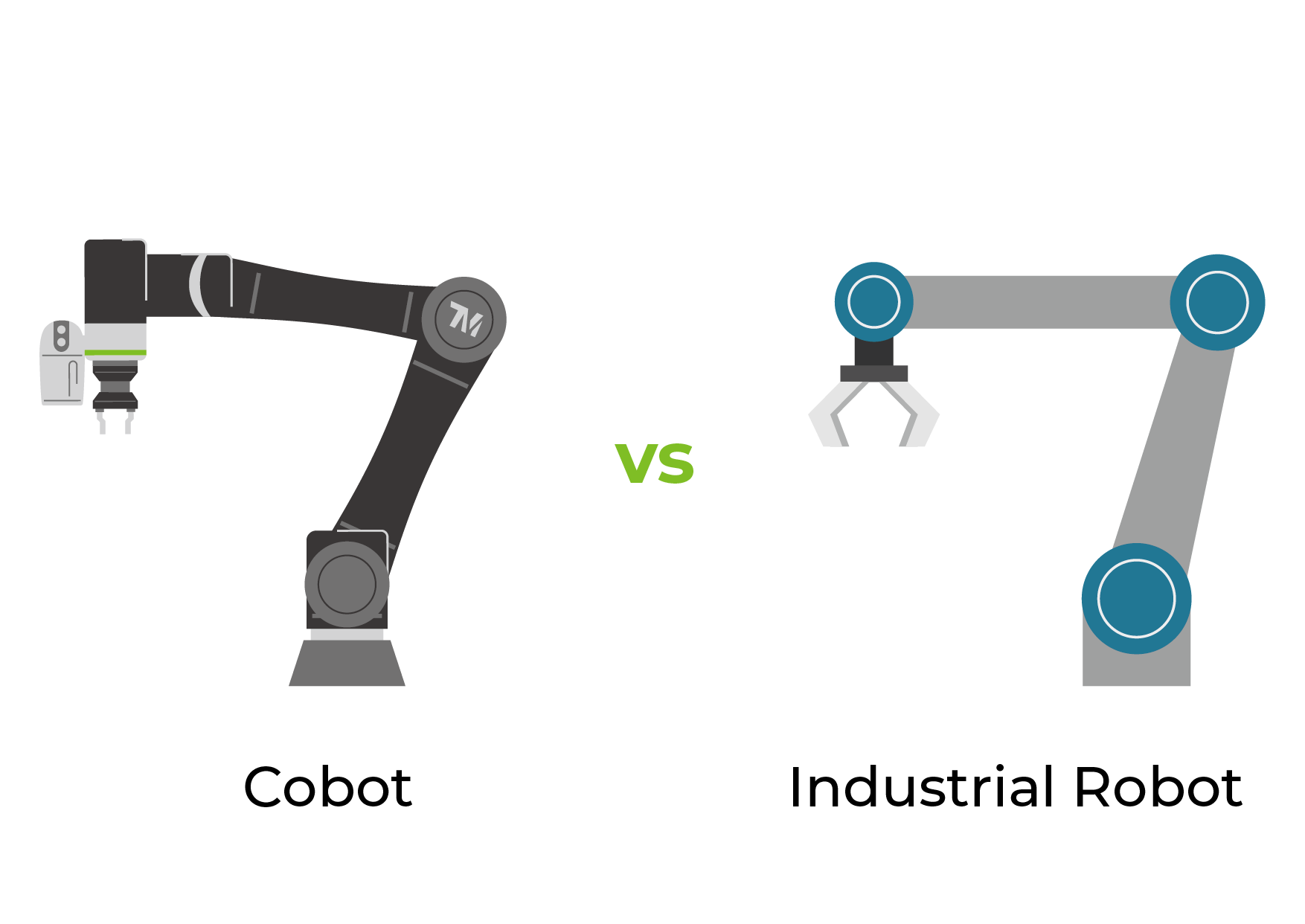

Cobots #

Unlike industrial robots, cobots are specifically engineered to operate alongside with human operators, offering businesses a safer and more efficient solution. Equipped with advanced sensing technologies and intuitive programming method, collaborative robots can adjust to environmental changes and collaborate with humans to enhance productivity.

- Lightweight, easy to relocated

- Designes to work alongside with human safely and more risk reduction from Cobot due to native safety function

Industrial Robots #

Unlike cobots, industrial robots are not intended for collaboration with humans and usually target to a dedicated workspace due to safety considerations. The primary advantage of industrial robots lies in their ability to execute highly demanding tasks in terms of heavier payload and longer reach.

- Designed for robust solutions in a dedicated workspace

- Risk reduction highly rely on building safety area and safety process control

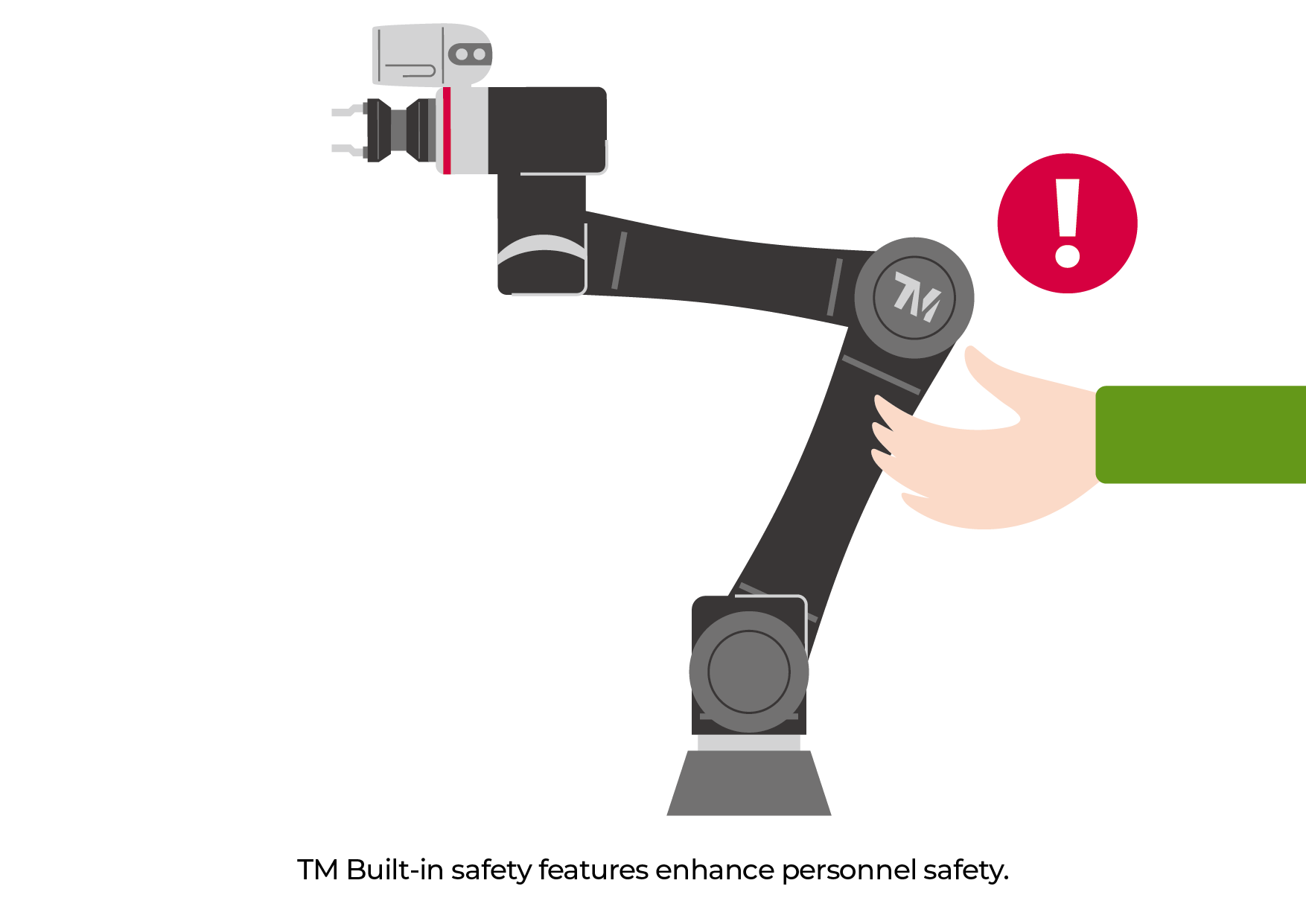

Safety First! #

When it comes to human-robot collaboration, safety is paramount.

TM robots feature overload-detecting sensing technologies and light weight designed, enabling safe operation in shared workspaces to reduce more hazard risk prevent from operator deviates from operational procedures. It will be possible to free the solid fence which saves lots of workspace in field.

The intrinsic safety functions, the robot is mush safer while operation, making robots a versatile and efficient solution for various collaboration applications and allowing operators to focus on tasks that require problem-solving and decision-making.

*under proper risk assessment analyze.

TM AI Cobots’ Collaborative Features #

Power and Force Limiting: #

TM robots are fundamentally equipped with Power and Force limiting safety function. This makes it possible for humans and robots to work together within the same workspace under a proper risk assessment carried out, which saves lots of workspace in field by cutting off the use of safety barriers.

The TM robot’s Power and Force limiting safety function under collaborative mode is design according to ISO/TS 15066 which fulfill the human-machine collision impact.

Hand-guided Control: #

This application can be used for point or path teaching, whereby the operator moves the robot head by hand to educate the TM robot to record to a position or predefined route. Meaning the elimination of distressed and time-consuming coding.

With TM robot’s hand-guided control, every point and pose in the task can be guided by hand whilst being able to change the degree of freedom of the hand-guide function easily according to the application.

TM AI Cobots’ Features #

- They are designed to be safe around humans either by intrinsic force & torque limiting function or external sensors that prevent harm coming to human nearby.

- Frequently they are light weight and can be moved from task to task, by being mounted on a portable stand for example.

- They are easy to program; if you can use a smartphone or tablet, you can program TM’s cobot.

- With AI and vision functions build in TM AI Cobot, a simple programming and ease of integration can be easier for integrators and cost-effective to purchase and maintain than traditional industrial robots.

Common Q&As #

- If an industrial robot integrated with a laser scanner or safety skins, why should I still choose TM AI Cobot?

- Although an industrial robot equipped with a laser scanner. According to the risks of using an industrial robot in previous page, if a worker violates the safety operating procedure and still gets in contact with the robot, there is still a chance of robot hitting onto the worker and creating serious accidents of death! The TM AI Cobot build in force and torque limiting function, which is an intrinsic safety measure to reduce risks and also to prevent such cases while the limiting values are properly set.

- Although an industrial robot equipped with safety skins, the risks of using an industrial robot may be reduced, but the integration cost will also be significantly increased. And, now there are only few safety skin makers and few of them achieve the required performance level (PLr) of PL=d, Cat.3, which is the basic and mandatory requirement from international ISO standard. Again, the TM AI Cobot build in intrinsic safety measures of force and torque limiting function, which is similar to effect of integrating safety skins, no additional cost with TM AI Cobot but still remain the required performance level from international ISO standard.

- If I still require safety barriers with cobot after my risk assessment, what is the benefits if using TM AI Cobot?

- TM AI Cobot is not just reduce more risk of the hazard for safety, but also smart! TM AI Cobot build in with AI and vision functions that saves lots of integrating effort in the your application field.