TM Robot

Stand-Alone Cobot Solution

Smart

Built-in Vision System

TM Robot is equipped with a built-in vision system, which integrates into both the hardware and software perfectly, comparing to the add-on vision for robotics that are more time consuming and costly to implement.

Simple

Painless Programming

Manage the functions and programming of your TM Robots using the TMflow™ — an innovative, flow-based editing software that allows you to program with simple click-and-drag motions. With TMflow™, you can create your own cobot projects without any coding.

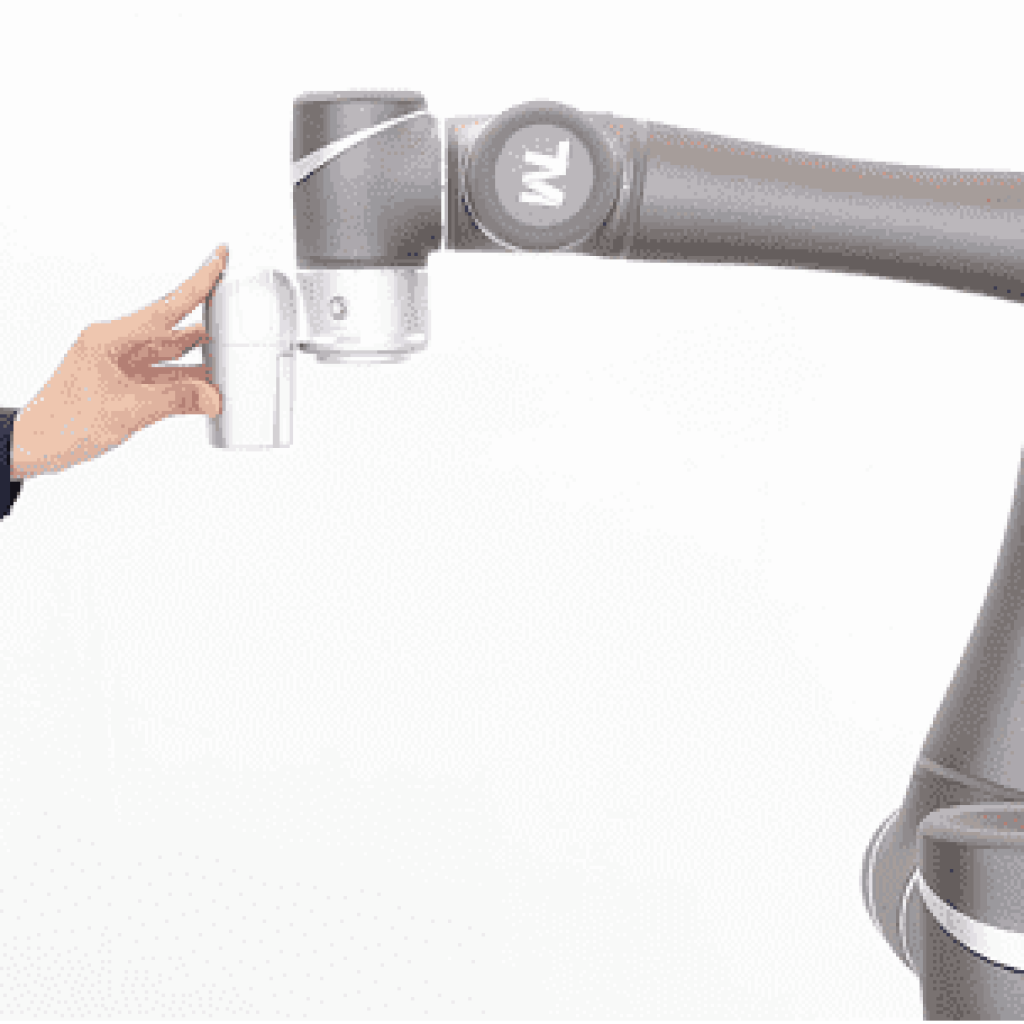

Safe

Force Limiting

Ensure the safety of your workers and any human who gets too close to or interacts with the TM Robot. These cobots stop immediately when they collide with any object, preventing further injury to both human and machine.

GET TO KNOW OUR TM ROBOT SERIES

Flexible Automation Regardless of Your Industry

We offer three series of cobot solutions — regular payload, medium-heavy payload, and mobile. These series represent various sizes and payload capacities to match specific tasks and requirements. Each stand-alone cobot solution includes a robot arm, equipped with TMvision and TMflow. We also provide task-compatible end effectors and peripherals (TM Plug&Play) that work together seamlessly. Our TM Robot mobile series can also be easily integrated with an automated-guided vehicle for applications that require mobility to switch between multiple workstations.

Choose the TM Robot that can best provide for your needs.

What is the difference between TM Robot and traditional robot?

TM Robot is a high-performance production tool that is highly compatible and flexible to man and machine collaboration. Compared to traditional industrial robots that require more manpower to maintain the rigorous workplace environment, our friendly TM Robot can safely do the work without such hassle. It demonstrates how companies can harness technology to work faster and better, and they don’t need to have millions in capital or a massive production to justify the investment. Cobots technology has gone through so many developments, they are now accessible and affordable to smaller business enterprises.

In an era that is trending towards quality over quantity, machines that can provide both can give you a competitive advantage. Go beyond traditional and choose collaborative robots. The TM robot will be your best option to help achieve a smart factory.

SMART

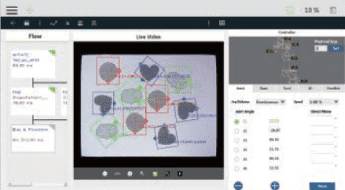

Built-in Vision System : TMvisionTM

Robot vision or the ability to “see” and interpret visual data into command prompts is one of the features that makes collaborative robots superior to traditional industrial robotics. TM VisionTM is a built-in, vision system that provides the user with friendly programming functions such as vision recognition, positioning, image enhancement, barcode identification, and so on.

Item detection module

Supports shape-based / image-based pattern matching, position alignment and irregular item detection to identify certain object within the vision field.Users can also use external image processing system to perform object detection and send the result back to TMvisionTM.

Image enhancement module

Supports contrast enhancement, image smoothing & thresholding, morphology, color plane extraction and image flipping.

Barcode identification module

Supports barcode/QR Code/2D DataMatrix reading, color classification and string matching. Users can also use external system to perform classification and send the result back to TMvisionTM.

Process-Oriented UI

TMvisionTM is a process-oriented user interface. It is easy to follow the software instructions and stack up the function process step-by-step, then your visual task will be ready to deploy in no time!

Visual Calibration with One Click

Just place the TM calibration board underneath the camera, and the rest of the calibration process is simplified to a click on the button for both EIH and ETH vision

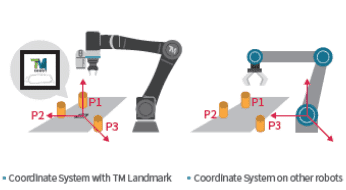

TM Landmark

This unique function allows TM Robot to scan the landmark and update the coordinate of all objects in the workspace without re-adjustment. TM Landmark is much quicker by breaking the traditional limitation of not being able to move the robot around.

SIMPLE

Replace traditional programming with intuitive interface and graphics

Patented technology lets operators with no coding experience to quickly learn and program their first robotic task.

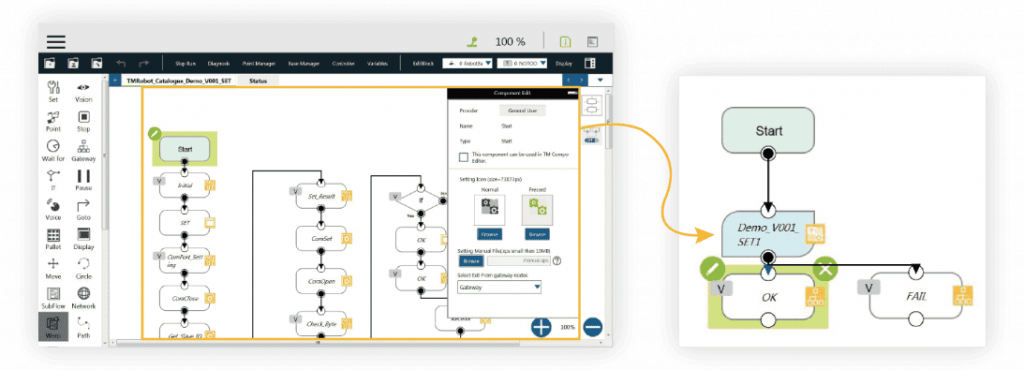

Painless Programming: TMflowTM

Take full control of the collaborative robots in your production or assembly lines. Thanks to TMflowTM, you can program each TM Robot to function precisely the way you need them to.

TMflowTM is a user-friendly, flow-based robot editing software that allows users to design cobot workflow. It is a simple, click-and-drag program which means programming knowledge is not a prerequisite for people to use it. Operators with zero IT background can also program a project in just five minutes.

Simplify Your Flow: TMflow Component EditorTM

Don’t want to waste time re-creating the same workflows in different robot tasks?

TM Component EditorTM provides you with the ability to wrap up and package compiled flows into components. You can use these components in your new projects to help shorten the time and effort needed to re-create them. By having customized components, it can also simplify your project process for faster editing.

Safe

Ergonomic Design and Force Limiting

Techman Robot complies with the ISO 10218-1:2011 & ISO/TS 15066:2016 human-robot co-operation safety requirements for collaborative robots. TM Robot can provide a pressure-free and safe environment for human operators to work in.

Safety Is Our Priority

TM Robot allows you to point out harmful human body parts that might be harmed by the robot in TMflow’s user interface. You can also set up speed limits for the robot arm when it is running in a collaborative workspace.

Furthermore, TM Robot is capable of performing an emergency stop when it detects a collision, minimizing the potential damage that might cause.

TM Add-on

Powerful Vision Add-Ons and Software Extension to Customize Your Perfect Robotics Solution

TMflow Editor

TMvision

Conveyor Tracking

TM ROS Driver

API Management

TMstudio

Techman Robot is not only a robot manufacturer. We are also dedicated to develop software and hardware solutions that are pre-integrated with our robot. TM Add-Ons can help you introduce cobots to your production line in a faster and easier way, such as implementing a conveyor tracking add-on, AI module, ROS driver and more!