Article by Frank Chen

Palletizing or de-palletizing is an essential stage in the modern production process. It looks like a pretty simple task. However, when the items are small or fragile, the workers need to handle them cautiously; When the items are large, it brings physical burdens to the workers; And no matter what size your package is, palletizing is meant to be a time-consuming job. From all perspectives, palletizing and de-palletizing are the most suitable applications for implementing automation solutions.

Though automatic palletizing solutions catch the eye of factory managers, there’s one problem that needs to be solved. Most of the solutions in the market are standardized solutions. The fact is, factory palletizing area has various layouts, a standardized solution can hardly fit into all kinds of production sites. Thus, a modification on hardware or software will be required. Either way, there will be additional costs. At Techman Robot, we are aware of this issue and launch the software pack – “TM Palletizing Operator Kit” can fulfill your need for a customized palletizing solution.

What is TM Palletizing Operator?

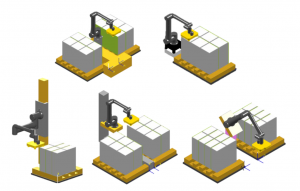

The goal of TM Palletizing Operator Kit is to help you build your own robot palletizing solution. You can design a preferable hardware layout with a robot arm, and used the software tools in the kit to edit the palletizing process.

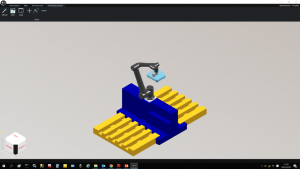

The TM Palletizing Operator Kit software pack is consists of two parts. TMstudio is an offline tool that includes Workstation, TCP generator, and Palletizing wizard for you to construct a virtual palletizing workstation. TMflow is the operating software of TM Robot that contains a pre-compiled project file that corresponds to the result generated from TMstudio.

When constructing a robot palletizing operator, you can set up a virtual scene by using TMstudio Workstation. Then you can import the 3D file of all required equipment such as the base of the workstation, pillar, conveyor, or others and define the coordination system. The next step, remember to consider that different items requires different robot end-effector, you can easily import the file of the end-effectors into the virtual scene and generate the center point by using a TCP generator. Now that the scene and equipment are all ready, you can start to set up project details such as palletizing mode, the size of the item and pallet, palletizing orders directions, and more with the Palletizing wizard. Finally, if you want to make some further adjustments against the motion of the robot arm, you can always edit the pre-compiled project file and make your changes.

For standardize palletizing solution, all of the customized adjustments can be done by requesting the solution provider or system integrator, with an additional bill of course. Another way to achieve this is by using the user software of the robot arm and create the whole palletizing task node by node. The creating process may be tough since you will need to take into account many details like the pose of the arm, the spacing between each item, how to adjust the pillar, etc. What’s more, the final flow could be large and hard to maintain. TM Palletizing Operator Kit is modularizing all important parameters and helps you to adjust them step by step, simplifying the development process, and shortening the automation time, and creates your customized palletizing operator quickly. After all, time is the money for the modern world of industrial manufacturing.

To learn more about TM Palletizing Operator Kit, please click here.

Or leave your information on the contact us page, we will contact you as soon as possible for product demonstration.