What is a SCADA System?

A SCADA Operating System refers to Supervisory Control and Data Acquisition systems, which provide monitoring, control, and data analytical capabilities to field devices from a remote site. SCADA operating systems, at its core, enable the critical efficiency of industrial operations through the collection and processing of real-time data.

A centralized system that serves to provide data monitoring and control access to supervisors, a SCADA operating system’s primary purpose is to maintain the efficiency in a wide range of industry sectors, such as manufacturing, transportation, oil and gas, power distribution, industrial plants, and more.

A SCADA system’s main components typically include the following:

- Human Machine Interface (HMI) software

- Data and Control or Communications Network

- Programmable Logic Controller (PLC) or Remote Terminal Unit (RTU)

- Equipment

With the emergence of Industry 4.0, SCADA systems have set the standard for automation opportunities – especially for businesses looking to scale in productivity.

The 4 Core Functions of a SCADA Operating System

To empower supervisors and managers to confidently run facilities from a remote site, SCADA Operating Systems primarily provide the following functionalities:

- Data Acquisition

- Networked Data Communication

- Data Presentation

- Control

Data Acquisition refers to the collection of data, which often utilizes conversion processes; such as measuring temperature, converting it to degrees Celsius, and transmitting signals in dBm.

Networked Data Communication, meanwhile, refers to the way SCADA systems transmit collected data. The communication channel can either be analog (T202, POTS) or digital (RS485, TCP/IP).

Data Presentation enables the collected data to be collected and aggregated for user viewing and decision-making. From tabular to graphical presentations, the processed data of logged actions and events is made comprehensive and accessible to users.

Control, lastly, is done through Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs), which allow the support of system commands, such as operational or configuration changes.

These four core functions allow SCADA systems to deliver a reliable tool in managing factories, industrial plants, and large-scale corporations.

Why is SCADA Essential to Automation?

A SCADA Operating System provides organizations with the capability to review pertinent data, evaluate situations, prepare for measured conditions, and execute automated responses in any given cycle. Through the precision and accuracy that machine control allows in a SCADA system, the risks involved due to human error is virtually eliminated, which makes automation a viable solution.

What to Look for in a SCADA Operating System?

When choosing a SCADA system for automation discoveries and opportunities, reliability and efficiency should always be a top consideration, especially for businesses with high volumes of product or service demand. Having enhanced network visibility is one factor that proves advantageous.

That said, here are the necessary tools and features to look for in a SCADA system:

- Programmable Response to Sensor Input

- Notification Features

- Graphical Display

- Capabilities for Expansion

- Geo-diverse Backup

- Flexible Support for Multiple Protocols, Tools, and Equipment

Programmable Response to Sensor Input refers to the SCADA operating system’s tools, and with ease of use, an effective SCADA system enables users to program derived alarms and manage soft controls. Derived alarms are virtual notifications produced by a variety of user-defined formulas, which are combinations of complex events tracked by sensor inputs and data reports, such as a machine’s shortage in power and a malfunctioning power source.

With a derived alarm tracking critical events, a SCADA system enables an automated response to take place, such as cascading these alarms to staff members and providing instructions. These derived alarms can be utilized to create notifications for an array of scenarios, aimed at preventing critical damage to operations.

Notification Features that allow programming is another key capability that makes a SCADA operating system efficient. For example; with 24/7 notifications enabled, a decision-maker has the capacity to find out and resolve a situation before a network outage leads to any losses.

From email to text message, and other platforms or methods for alerting, a SCADA system’s notification features are important in maintaining daily efficiency and emphasizing reliability.

A Graphical Display is another necessity in providing an in-depth and user-friendly experience to a SCADA operating system’s interface. A visualization of alarms on layered geographic maps, for instance, makes the job of operators much easier, especially when they are searching through regions and cities for equipment sites that need repair.

Capabilities for Expansion is another important consideration, as SCADA systems are a long-term investment. An effective SCADA system will have the capability to support the company’s potential growth for at least a decade.

Instead of replacing operating systems every so often, implement a scalable and cost-effective solution to reduce the need for transitionary processes and sustain operational continuity.

Another important feature is having a Geo-diverse Backup, which refers to a SCADA operating system that supports redundant master stations, should any calamity or emergency threaten to disable network service and visibility. As mentioned earlier, reliability is key, and it always helps to have a secondary master station synchronized with the primary master to prevent any issues due to network impairment.

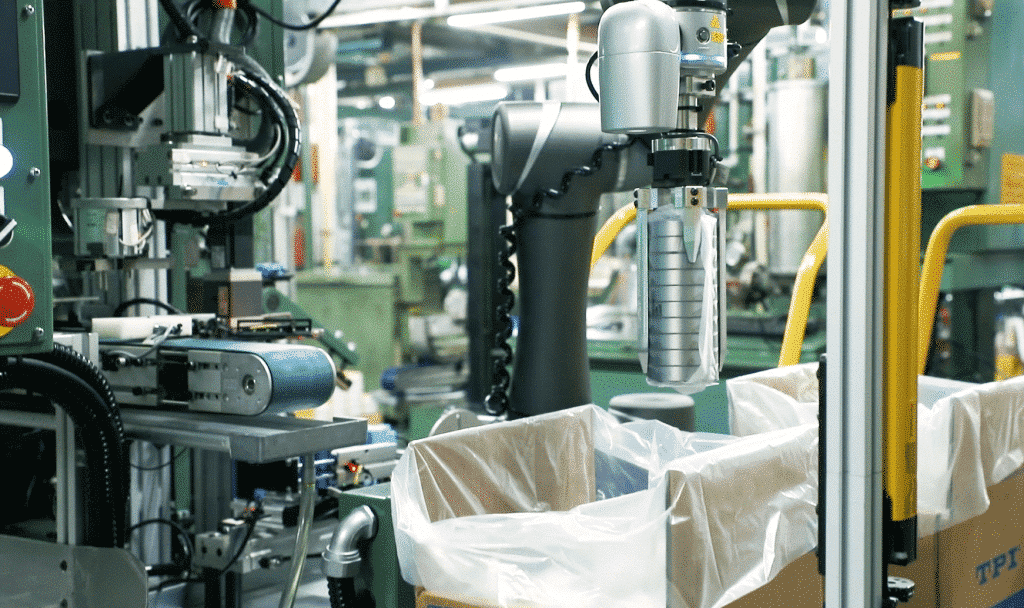

And lastly, Flexible Support for Multiple Protocols, Tools, and Equipment is critical to a SCADA operating system for the advantages it can deliver to a range of manufacturing industries. Automation, for instance, is made possible through processes such as cobot integration.

The management of collaborative robots in the workplace requires the use of data in the implementation of processes and improvement of operational tasks, and a flexible SCADA system that supports multiple protocols can provide the insightful information for this integration to be successful. Without the necessary data, flexibility and support features, how can cobot integration improve production in the assembly line?

Techman Robot’s SCADA Operating System for Automation Solutions

Automation unlocks a diverse range of discoveries and opportunities in the manufacturing industry. And with the implementation of an effective SCADA operating system, a company looking to automate its processes and improve its capabilities is well-positioned towards the Smart Factory Era.

Techman Robot’s TMmanager is your SCADA system for cobot automation, a high-performance factory management software that makes it easy to monitor, access, and control factory operations through a range of solutions such as:

- Usability

- Data Security

- Alarm System

- Open Data Interface

- Robot Management System

- Shop Floor Control System

We believe that with the right robotic technological applications set in place, any industry can impact the way things are done – improved performance, better overall efficiency, and cost-effective productivity.

For more info, questions, or inquiries, contact us today.