The Prevalence of AI

When we talk about artificial intelligence, or AI, we tend to think about advanced and cutting-edge systems just like in the movies – and while we’re not wrong – AI is available in more objects and appliances than we realize.

To summarize, there are four types of AI:

- Reactive machines

- Limited memory

- Theory of mind

- Self-awareness

Through these four types of AI, our lives have been impacted, and many industries have grown and developed to improve the way manufacturing works. From processing, storing, and analyzing data to creating algorithms, manufacturing can benefit from the insights that AI provides.

The 4 Ways AI Impacts the Manufacturing Industry

While there are multiple and specific ways that AI can influence manufacturing processes, highlighted below are four of the significant benefits that the industry can leverage through smart manufacturing:

- Improved safety in the workplace

- Quality performance and precision

- Opportunities for innovation

- Reliable inventory management systems

Improved Safety in the Workplace

Cobots or collaborative robots, for instance, serve to provide hybrid work environments designed to keep human workers safe from hazardous tasks by reducing risk in execution or operations.

Cobots can help any manufacturing company shift towards smart manufacturing through improvements in repetitive tasks in the workplace. By replacing human workers in the assembly line, for example, cobots can assist in the creation of safer manufacturing environments, thus allowing for improved safety—enabling workers to concentrate on more critical and complex tasks, resulting in better overall worker satisfaction.

Machine learning, which is among AI’s features, addresses a number of challenges involved in the implementation of robotics in manufacturing systems. By analyzing data and identifying changes in a pattern, a manufacturing robot can react accordingly.

One example of this is how cobots can be programmed and reprogrammed to react to deviations in the manufacturing process, such as knowing when to discard a product or proceed with the designed sequence of events.

Quality Performance and Precision

To truly deliver high-quality products and goods, a certain standard must be met. AI and smart manufacturing improve manufacturing processes and help in assuring that these standards are met accordingly.

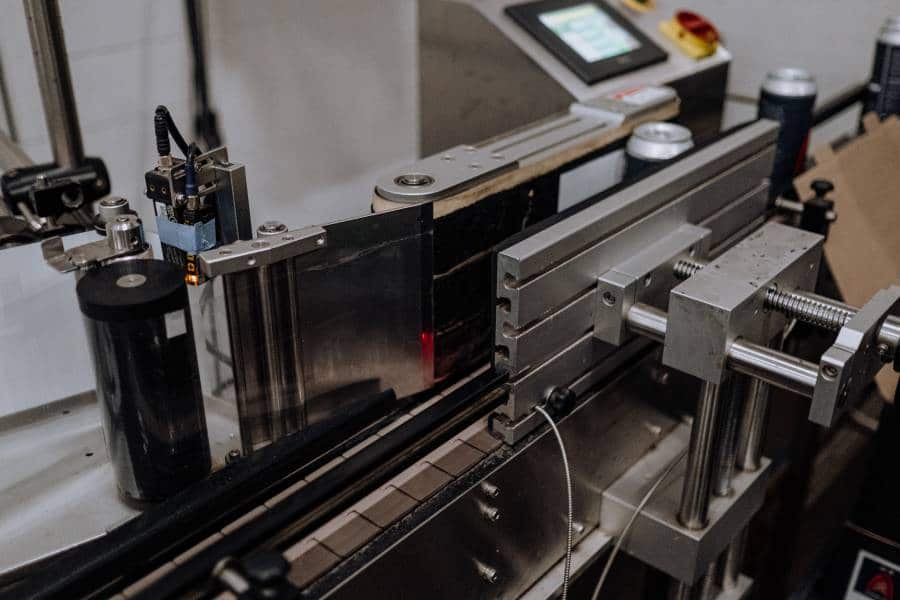

Through quality control systems like machine vision, manufacturers can benefit from an AI’s precise evaluation of every product that goes through an assembly line—even before these goods and services find their way to the customer’s hands.

This allows manufacturing companies to enjoy an untarnished reputation when it comes to the quality of their products. It also enables data collection, which can help further product or process iterations, influencing better decision-making later down the line.

Opportunities for Innovation

Through technological advancements, such as industrial robots, manufacturing companies have developed and innovated. Including AI and implementing artificial intelligence in manufacturing systems enable these companies to discover opportunities to be creative, if not more efficient, in terms of production.

New product designs, for instance, can be developed through the combination of AI and engineering. Smart self-driving cars and smart homes are examples of innovative ventures that rely on artificial intelligence.

Reliable Inventory Management Systems

Forecasting, making projections, and inventory planning are necessary steps for efficient manufacturing companies. Implementing AI platforms, such as machine learning, can help improve inventory management through efficiency, accuracy, and cost-effectiveness—especially when compared to traditional forecasting methods.

With reliable inventory management, a manufacturing company will see improvements in their bottom line.

AI is Key to Smart Manufacturing

With smart manufacturing brandishing a variety of advantages such as automation, data analytics, and digital information technologies, the implementation of AI in can help revolutionize how things are executed.

Through safer, more efficient, and innovative processes that lead to high-quality products, any manufacturing company can enjoy the benefits that come with a workplace empowered by artificial intelligence.

Want to learn more about smart manufacturing? Visit our blogs or send us a message today.