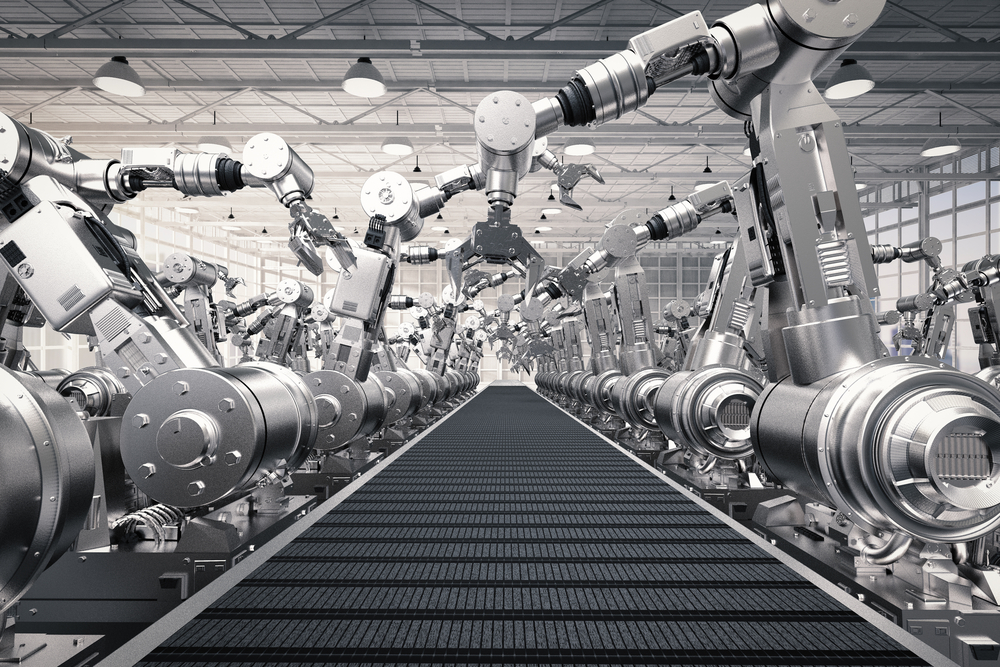

Collaborative types of industrial robots (AKA cobots) are becoming hugely popular in manufacturing. These types of industrial robots can work alongside human workers to assist with repetitive, dangerous tasks or require high precision. Safety barriers typically separate standard robots from human workers, but cobots are designed to work with humans, unlike traditional industrial robots. In this article, we’ll take a closer look at the different types of collaborative robots available and the industrial robot applications they are suited for.

An Overview of Industrial Collaborative Robots

Cobots are types of industrial robots designed to collaborate with human workers in close proximity easily. They are equipped with sensors that allow them to detect the presence of human workers and stop or slow down accordingly. This ensures that they work safely alongside their human counterparts. These types of industrial robots are also easy to program, allowing manufacturing or industrial workers to integrate them into their existing workflow.

Types of Industrial Collaborative Robots

There are many different types types of industrial robots available. Each type of cobot has its own strengths and limitations, and choosing the right one will depend on factors like the type of task, the size of the workspace, and the level of human interaction required. Let’s take a look at the different types of cobots available.

Power and Force-Limiting Robots

Power and force-limiting robots are designed to automatically stop when they come in contact with a human worker. They have built-in sensors that detect when the robot is about to collide with a human worker, and the robot will immediately stop to prevent any injuries. These robots are typically used in assembly, packaging, and machine tending tasks.

Safety-Monitored Stop Robots

Safety-monitored stop robots use sensors to detect when a human worker is nearby and slow down or stop accordingly. These robots are ideal for tasks that require frequent human-robot interaction, such as welding, painting, and quality control.

Hand-Guided Robots

Hand-guided robots are types of industrial robots operated by human workers who physically move the robot. These robots are suitable for tasks requiring precise movements, such as polishing and deburring.

Speed and Separation Monitoring Robots

Speed and separation monitoring robots use sensors to detect when a human worker is close and adjust their speed accordingly. These robots are ideal for tasks that require frequent human-robot interaction, such as pick-and-place operations and palletizing.

Mobile Robots

Mobile robots are designed to move around the workspace and assist human workers in various tasks. These robots are typically used in tasks such as material handling, logistics, and warehouse management.

Dual-Arm Robots

Dual-arm robots are designed to mimic the movements of human arms and are ideal for tasks that require high precision and dexterity, such as assembly and packaging.

Collaborative SCARA Robots

Collaborative SCARA robots are designed for tasks that require high speed and precision, such as pick-and-place operations and assembly.

Teleoperated Robots

Teleoperated robots are operated by human workers from remote locations. These robots are typically used in hazardous environments, such as nuclear facilities and chemical plants.

Exoskeleton Robots

Exoskeleton robots are designed to be worn by human workers and assist in tasks that require physical strength, such as heavy lifting and repetitive motions. This can be particularly useful in warehouse environments when heavy lifting is required.

AI Cobots

AI cobots are equipped with advanced AI and machine learning capabilities that allow them to improve their efficiency over time. These cobots are ideal for various applications, including material handling, AOI inspection, and palletizing.

Why Invest in Industrial Collaborative Robots?

So, why should you invest in an industrial robot? There are many reasons why different types of industrial robots can lead to significant improvements within an organization. The main reasons to invest in a cobot for working within the manufacturing industry are:

- Cobots increase productivity by taking on repetitive or dangerous tasks, allowing workers to focus on more complex work. This can result in improved product quality and faster turnaround times.

- Cobots can reduce costs by minimizing errors and waste and reducing the need for human workers to engage in physically strenuous or hazardous tasks.

- Cobots can improve worker safety by providing a safe and ergonomic way to perform tasks that would otherwise be hazardous or difficult for human workers.

Choosing the Right Type of Industrial Collaborative Robot

Choosing the right kind of cobot is essential for success within your manufacturing warehouse. Each cobot will have its own strengths and limitations, so take time to select the one most suited to your needs. Factors to consider include the size and layout of the workspace and the amount of human interaction required.

It’s also worth considering AI types of industrial robots, equipped with machine-learning capabilities that allow them to improve their efficiency over time. AI cobots are an investment in the productivity and efficiency of a workplace that can be a long-term solution to a variety of issues.

Industrial Applications of Collaborative Robots

Cobots can be used in a variety of industrial applications. These industrial robots can carry out tasks such as material handling, assembly, packaging, product inspection, and more! In the automotive industry, cobots are used to assemble and paint cars, while in the food industry, they can quality check and package food products. Cobots can also perform precision assembly and inspection tasks.

Collaborative types of industrial robots have revolutionized manufacturing and other industrial applications by providing a safer, more efficient, and cost-effective way to complete tasks. By selecting and investing in the right cobot for your working environment, organizations can achieve greater productivity and increase efficiency while reducing risk and hazard within the workplace.

Techman Robot’s AI cobots are equipped with advanced Al and machine learning capabilities that enable the cobots to increase their efficiency over time. These cobots are known for their built-in smart vision system, providing ease of use and versatility, ideal for a wide range of applications, including material handling, AOI inspection, and palletizing. Click here to discover the range TODAY!