We are all familiar with the concept of automation, especially factory automation, given the prevalence of industrial robots. When thinking of automation, most of us would probably be able to equate it to assembly line production in factories. While this is indeed one use for machine automation, there are actually many types of automation equipment and processes used in various different industries today. Two of the most common examples of industrial automation are factory automation vs process automation.

What are Factory Automation and Process Automation?

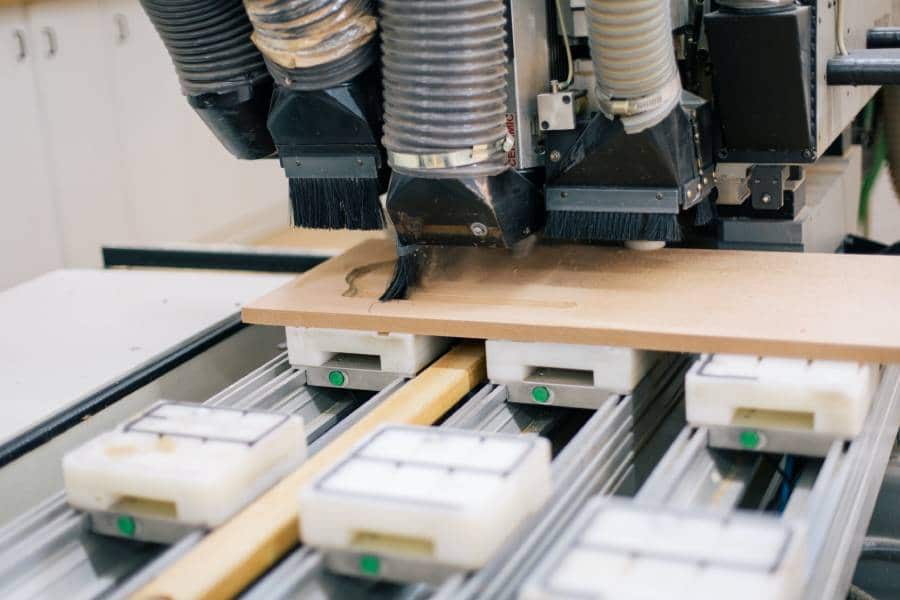

Machine automation is basically the use of control equipment to perform manufacturing operations. Machine automation can be used in all phases of manufacturing, from processing, inspection, testing, assembly, packaging, and final delivery. There are two main types of factory/machine automation: machine or process automation, and full factory automation.

Process Automation is defined as use of control equipment to perform manufacturing operations on individual pieces, subassemblies or batches of products. The objective here is to improve the speed or quality of production by minimizing labor requirements or increasing machine speed/capacity with the same labor content.

Factory Automation involves using programmable logic controllers, computers and other control equipment to automatically sequence or operate entire production lines. The objective here is to speed up the entire production process from order entry through final delivery with no manual intervention.

Difference Between Factory Automation vs Process Automation

Factory automation, for instance, can be categorized further according to these automation types: fixed, programmable, and flexible automation.

Fixed automation is relatively fixed and inflexible in terms of the cells it can handle. It’s not possible to change a fixed cell line easily, without considerable cost and plant downtime.

Programmable automation allows for quick changes to product types, part numbers or production quantities within a single cell. The type of product or quantity to be produced is usually determined by the programming of computer systems that are directly linked to cell controls.

Flexible automation allows for quick changes to product types, part numbers or production quantities within a single cell with minimal cost and plant downtime. The type of product or quantity produced can be changed using an ergonomically designed MMI (Man Machine Interface) that is also directly linked to the cell controllers.

At its core, factory automation is a holistic industrial process which, through automation, serves to reduce risk and harm to human works with increased automation in the tasks and production processes in a plant. While process automation focuses on automating industrial control applications used in the operation of factories, plants, and other industrial facilities.

Similarities Between Factory Automation vs Process Automation

Factory automation is basically process automation on a larger scale, but there are still many similarities between the two. For both factory and process automation, changes to products or processes are usually made by human operators rather than automated equipment. While process automation is used at a cell or group of cells within a factory, factory automation is used to automate an entire production line, from order entry through final delivery.

Process Automation can be used in all phases of manufacturing – from processing, inspection, testing and assembly – whereas factory automation is most commonly used for assembling products from parts.

Process Automation is commonly used in discrete or batch type operations, where products are made one at a time. Factory automation involves the use of lines that handle continuous material flows where products are assembled continuously without human intervention between operations.

How do Factory Automation vs Process Automation Affect Quality?

Normally, quality concerns with process automation involve the loss of line synchronization between the product being assembled, the equipment that performs the assembly operations, and input/output devices that provide part or material data for processing.

With factory automation, quality concerns typically involve maintaining synchronization throughout an entire production line. This requires close coordination among machines performing different steps in the process, as well as input/output devices providing part or material data.

One of the main benefits of factory automation is an increase in process quality as machines can provide superior accuracy, repeatability, and speed. The biggest challenge with factory automation is also related to quality as there are many more components that could go wrong versus a simple process line.

A number of things have to be considered before choosing factory automation vs process automation. In general, if a high degree of flexibility is required and there are capable operators who can handle setups and make minor adjustments, process automation may be the way to go. If you need a higher level of accuracy or require multi-shift operation, then factory automation may be an easier and more practical solution. When in doubt, it’s usually best to hire an automation consultant or expert who can help you make the right decision.

Send us a message for more factory automation, as cobots serve to automate a variety of tasks in a wide range of industries, from food processing to manufacturing, construction, retail and more.