For factories, better productivity and quality are important factors which managers are always in pursuit of. However, while these managers are aiming for a higher goal, they cannot overlook the risk and extra workloads that might be imposed on their workers. How can the factory reach for a better performance while not sacrificing workers life quality and health? Techman robot has provided a solution.

Leave the Heavy Parts to Cobot Arm

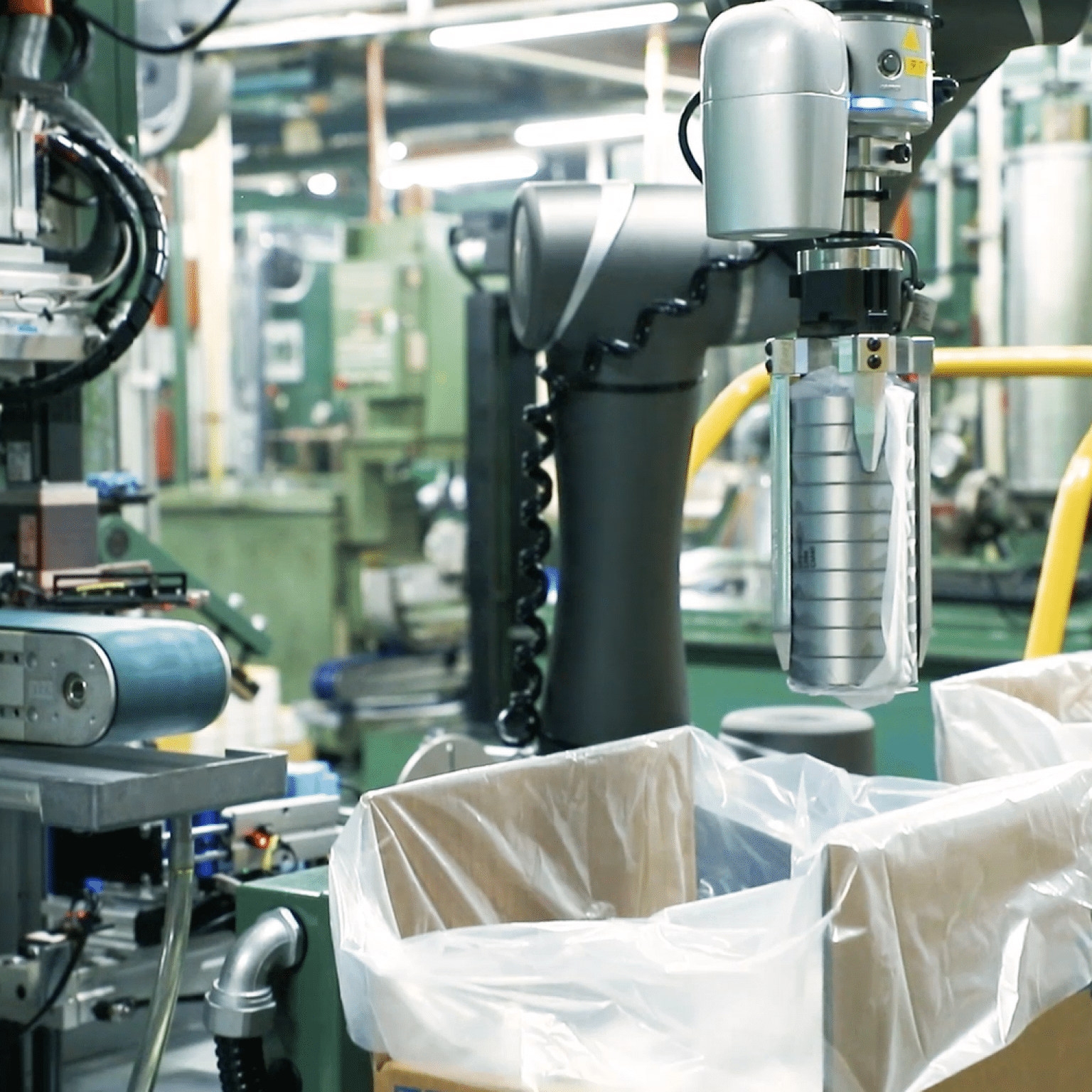

Tung Pei Industrial Co. is a Taiwanese manufacturer that produces industrial bearings. In the packaging stage of the production, the factory used to have human workers load the packed bearings into the cardboard box. Since the packed bearings are very heavy, the packaging process creates great loading that will accumulate and do harm to workers’ forearms.

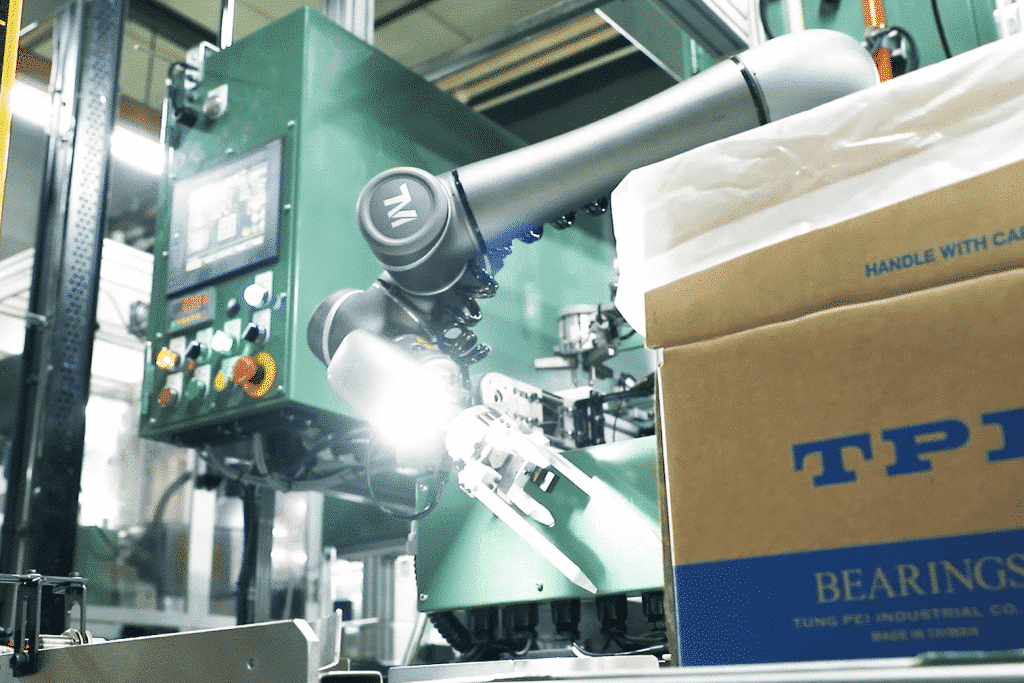

“One biggest benefit that introducing TM Robot brings to us is that it truly reduces a lot of our worker’s physical loadings.” Says Chia-Chin Chen, the section manager of Automatizing Scheme Department. “One another TM Robot feature that we really like is its 6-axis design. Comparing to a 4-axis robot, the extra 2-axis enhances its movement flexibility and allows it to imitate the movement of human arms, and insert the packed bearings into the cardboard box fluently.”

Using Embedded Vision to Enhance Utilization Rate

While the implementation of TM Robot solves their worker’s health problems, its payload capacity is not the only strength that is leveraged by Tung Pei Automatizing team. TM Robot is also assigned the task of reading the barcode on the box. “We have multiple kinds of cardboard boxes on one production line. We decide to use the embedded vision functions of TM Robot to read the barcode on each box. Then the cobot arm itself can determine the packaging way of the boxes. In this way, we not only reduce potential human errors but also enhance our utility rate. Because now our workers no longer need to help with packaging process while they are in the middle of the other tasks. So the productivity of the entire line is able to increase.” says Zhong-Xiang Yang, TPI production line engineer.

Overall, the implementation of TM Robot provides both the workers and the enterprise a win-win result. The workers can now stay in a healthier condition and extend their potential career since their physical workload is reduced. The enterprise is also benefits from happier workers and a better productivity production line.