Recruiting Distributors in Southeast Asia

We, Techman Robot, are a Taiwanese brand and manufacturer of collaborative robots with embedded vision systems, software, and application-based solutions. We are also the world’s second-largest collaborative robot brand with over 100 distributors in Europe, North & South America, Japan, South Korea, South-East Asia, and Oceania markets.

We are expanding our distribution network and looking for new partners in Southeast Asia, especially in Malaysia, Thailand, the Philippines, Indonesia, and Myanmar. Join our global network and strengthen your business by collaborating with Techman Robot. To become our distribution partner, please get in touch with us at Francine.chu@tm-robot.com and Brian.huang@tm-robot.com.

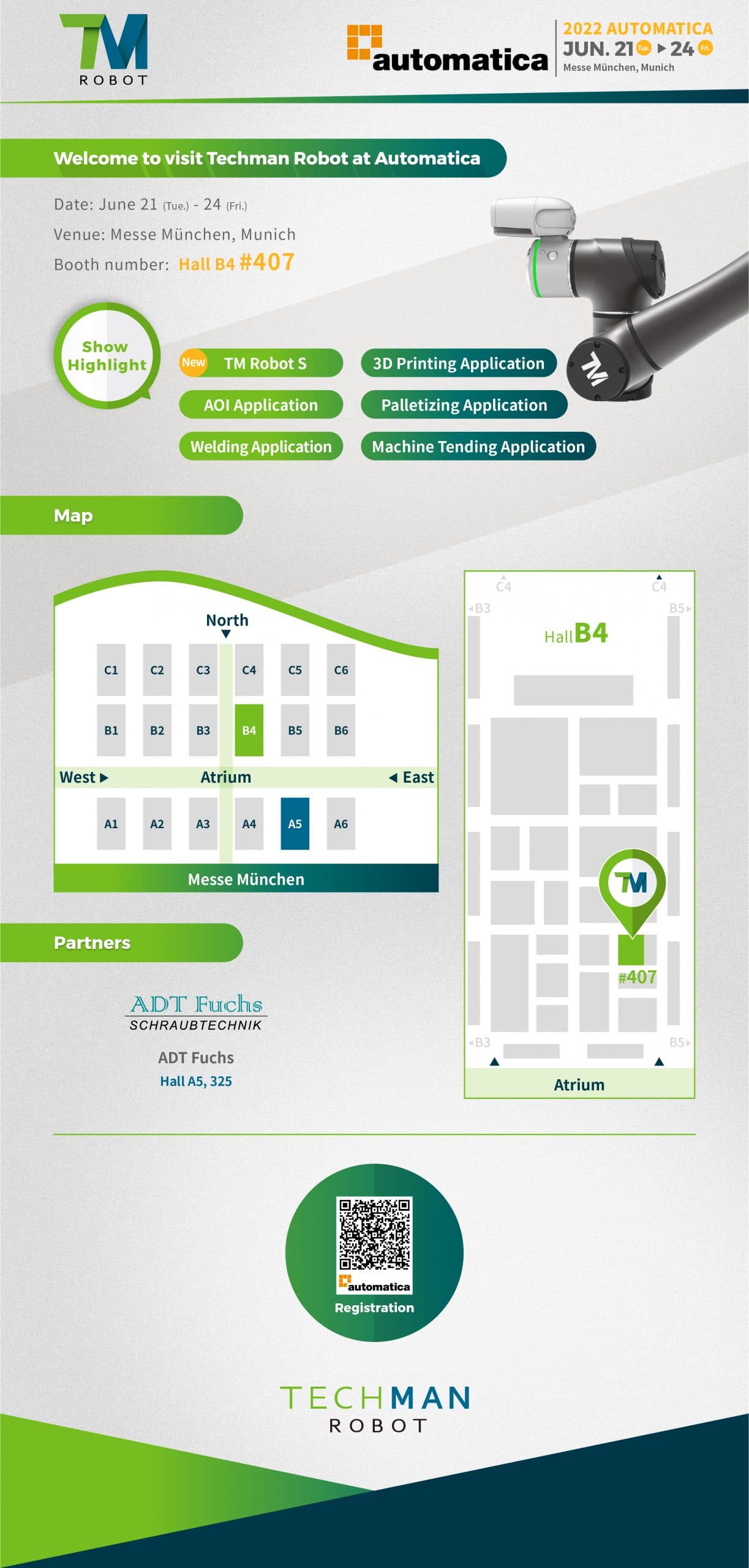

Welcome to visit Techman Robot at Automatica 2022

Welcome to join Techman Robot at iREX 2022

Join our Global Network! Recruiting New Distributors

Techman Robot is expanding its distribution network and looking for new sales partners in the UK, Spain, Germany, France, and the US especially in Northeastern, Western area and Texas., who are willing and capable of developing international growth together with us. Automation experience is a plus.

Techman Robot is the second-largest collaborative robot brand in the world and offers collaborative robots with embedded vision systems, software, and application-based solutions to the market, through more than 100 distributors in China, US, Europe, Japan, South Korea, and Southeast Asia.

Join our global network and empower your business by collaborating with Techman Robot. If you are interested in becoming a distributor, please contact us at tmsales@tm-robot.com.