Since the inception of cobots in many business sectors and a wide range of industry processes, the logistics and warehousing industry has also seen a rise in productivity and efficiency, thus enabling various service providers the capability to meet the increase in demand. Cobot technology continues to develop, and with the emergence of Industry 4.0, supply chain efficiency and the warehousing industry can keep reaping its rewards.

The Role of Cobots in the Warehouse

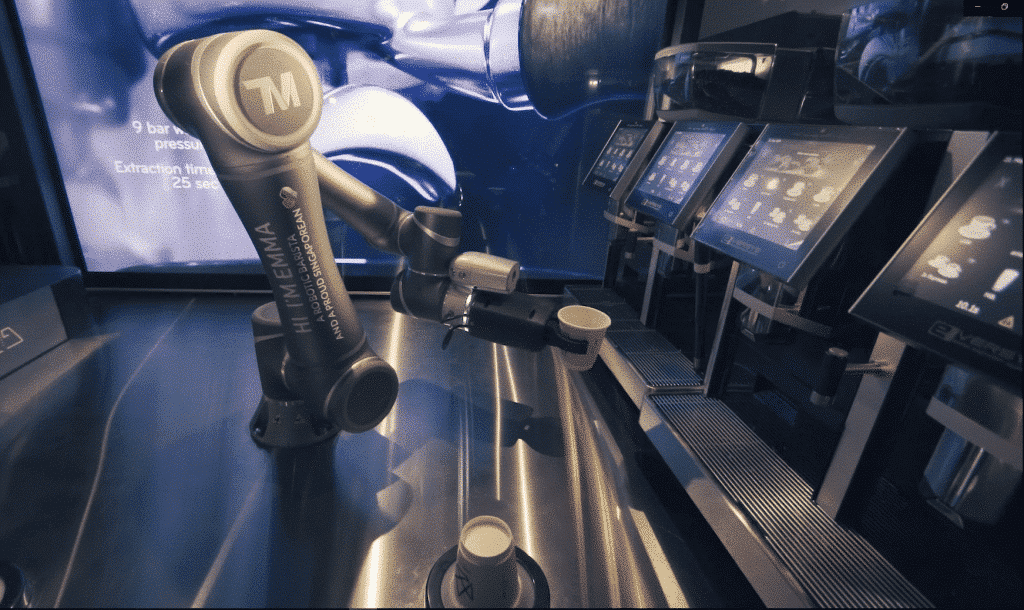

As they are built and designed to work collaboratively with humans in any given workspace, such as warehouses and distribution centers, cobots perform different tasks that serve to reduce the risk for any human injury. Through artificial intelligence (AI) and machine learning, cobots function effectively and efficiently as programmed.

In the logistics and warehousing industry, cobots provide long-term value through operational reliability in executing the tasks that can be automated. This means that any company will free up bandwidth in the workforce, effectively allowing the organization to utilize resources, such as manpower, towards value-adding activities like data analytics, strategy planning, quality control and assurance, or making important business decisions.

With cobots in the warehouse, logistics companies can enable higher rates of picking and palletizing while reducing injuries in the workplace.

The Benefits of Cobots in the Warehouse

Given the role of cobots in the logistics and warehousing industry, here are the five benefits it primarily offers:

- Enjoy a safer workplace and risk-free environment. Warehouses are no stranger to safety hazards, which can ultimately affect your bottom line. From lower productivity rates to higher, more frequent costs due to compensation expenses, a safe workplace not only addresses these issues, but it improves morale. The implementation of cobots in the warehouse reduces the physical toll on staff, enabling a healthier and stronger team operating the machines, as well.

- Experience less instances of human error. Human workers make mistakes every now and then—it’s natural and it can be addressed through various means. Cobots, on the one hand, are efficient. Programmed to help guide users in the execution of different tasks, there are cobots with built-in precision and accuracy features that add another layer of quality control.

- Enable an increase in productivity. As mentioned earlier, logistics and warehousing companies can expect to benefit from the implementation of cobots through improved production, faster turnaround times, and optimized processes for better efficiency. This enables workers to prioritize more complex tasks that can impact revenue. After all, with tireless reliability, cobots will perform—rain or shine—allowing return on investment (ROI) sooner than later.

- Ensure lower operating costs over time. With cobots taking over certain tasks in operations, a warehousing company reduces their operating costs after getting their ROI. With less rework necessary due to human error, alongside increased efficiency and decreased injuries due to accidents in the workplace, a warehousing company will eventually incur less expenses by way of operations. It is more likely that there will be a need to expand due to increasing capacities to deliver.

- Expansion is possible through flexible and scalable installation. Another feature of cobots that serve as an advantage to warehouse applications is its capacity to collaborate on various tasks in the supply chain. Through modular and adaptive robotics, a company can utilize cobots according to the season. This allows logistics and warehousing companies to maximize a range of collaborative robots in operations without spending on additional resources when demand starts to peak.

Cobots in the Warehouse: Yes or No?

The definitive answer is yes. With the latest developments in cobot technology, human workers and robots in the logistics warehousing industry can only spread in prevalence, especially with the benefits that collaborative work offers. Automation is an undeniable factor that impacts the workplace—indeed, it will replace some workers but it will also create opportunities for more specialized, value-adding jobs.

That being said, cobots can help logistics installations perform better through increased productivity rates and safer workplace environments. There is nothing to fear with the popularity of cobots in the warehousing industry, because it truly serves to complement existing processes as it builds and improves the quality of workflow in operations.