As a manufacturing business owner, the thought of automation must have surely crossed your mind more times than ever, especially in light of the pandemic. That being said, the question remains, “Why should you automate your manufacturing assembly line?”

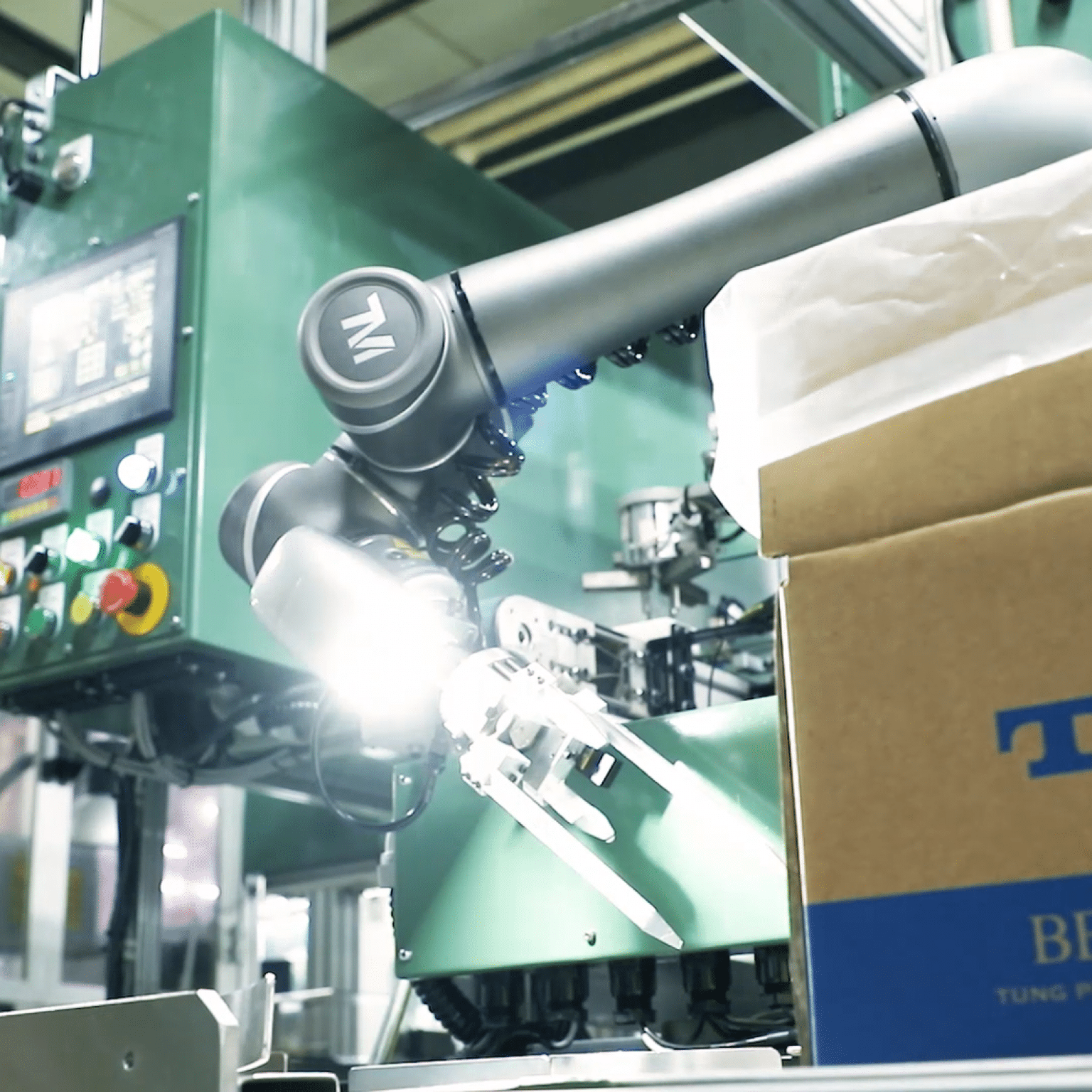

Since an automated assembly line is composed of several workstations connected through a transfer and electric control system, the need for human intervention in operations is reduced and reallocated towards quality-intensive tasks. With every workstation designated to perform a particular task, a product undergoes a series or sequence of processes as it is manufactured through the assembly line.

It is through mechanical equipment and automation that a fully automated assembly line will have no need for operators or staff to be directly immersed in the process. This allows a manufacturing company can realign workflow processes and adjust resources towards the following tasks:

- Systems Design

- Product Adjustments

- Operations Supervision

- Task Monitoring

Instead of spending bandwidth on controlling and operating the assembly line through manual processes, automation in the workplace, such as in assembly lines, a company can deliver more value through better quality goods, products, and wares or providing improved services.

The Three Types of Automation in Manufacturing and Production

There are three known types of automation in manufacturing and production:

- Hard or Fixed Automation

- Programmable Automation

- Soft or Flexible Automation

Relative to the type of industry manufacturing that a company is involved in, each automation type can be applied accordingly.

Hard or Fixed Automation

This type of automation refers to the utilization of equipment specialized to target and implement a fixed sequence of processing and assembly operations. These sequences are usually composed of simple operations, such as a linear or rotational motion, which can also be a combination of these in uncomplicated patterns. This type of automation will present challenges to customizations and revisions in product design.

The benefits of hard automation include:

- Automated material handling

- Cost-effective

- High rates of production

Programmable Automation

This of automation, meanwhile, allows for frequent changes in product design, such as upgrades, tweaks, and adjustments, through automation equipment that offers the capability to be programmed or reprogrammed accordingly. The sequence of assembly is controlled by a programmable configuration that allows for different designs for production.

The benefits of programmable automation include:

- Flexibility to accommodate variations in product design

- Suitable for batch production

Soft or Flexible Automation

Lastly, this type of automation in assembly lines is similar to programmable automation in that it is offers the extended capability of programmability. This means that it allows for limited modifications, such as in the production or assembly of various parts, without compromising timeliness and resources. There is no disruption in manufacturing as the system is reprogrammed and the physical setup is modified.

The benefits of soft automation include:

- Seamless production and assembly processes of variable designs

- Flexibility in variants of product designs

Is It Worth Automating Your Assembly Line?

A fully automated assembly line enables the manufacturing of the end product without barely any human intervention. This means that a manufacturing company with automated assembly line enjoys fast, consistent, and precise production, which leads to reduced production times and decreased costs to produce. If it’s worth experiencing significantly higher production rates with less costs, zero human error, and accurate output with every run, then the question to ask is: “Is your business ready to be automated?”

Depending on the industry your business is involved in and the type of products in assembly, choosing between the different types of automation in production should be much easier. Check the benefits and align these with your operations to find out which type is most suitable.

With less repetitive tasks in the pipeline, an automatic assembly line offers key benefits that can help push a business closer to their goals and objectives.

Read more about automation and smart manufacturing in our blog page.