It cannot be denied how the COVID-19 pandemic has brought about unprecedented waves of change in the past couple of years, and it continues to impact industries all over the world, causing shifts in many manufacturing operations. Among these changes is the move to a work from home setup, primarily due to social distancing protocols that serve to prioritize worker health and safety. While easier to execute in certain industries, supply chains aren’t as pliable, thus highlighting the importance of a factory management software, a business’ manufacturing enterprise resource planning platform (ERP), and their capacity or readiness in BCP/DR, or business continuity planning and disaster recovery.

This is not to say that the impact of a factory management software and its capacity to affect change in a company has gone unappreciated. Take, for example, how it has served as the primary system that holds operations together during changes in management, process improvement programs, and unforeseen disasters—fires, floods, or accidents of the technical kind. The crux of the conversation is in its massive and widespread growth in use during the pandemic.

The Key Benefits of Factory Management Software During the Pandemic

Here are the ways that effective factory management software has enabled companies to sustain operability in lieu of COVID-19:

- Allowed for remote working setups

- Automated reporting and monitoring updates

- Electronic data exchange and open cloud accessibility

- Real-time factory controls

Leverage the advantages of utilizing an integrated ERP system and ensure undisrupted operations in challenging times through:

- Enabling and empowering staff to utilize hybrid working setups

- Sustaining production at the workplace and meeting project timelines even with staffing issues or supply/material deficiencies

- Managing and optimizing shifting according to demand

Enabling Hybrid Working Setups

Many industries have gone on to manage staffing by maximizing as much personnel in work from home setups while utilizing hybrid setups for crucial roles required in the manufacturing plant and offices. From administrative staff to planners and designers, effective production management platforms have empowered companies to implement this shift without causing major disruptions at the workplace.

Front-office staff can fully execute their tasks through integrated factory management software from the comfort and safety of their homes. This allows for seamless business continuity and client-compliant interactions or supplier communications. Whether through smartphones, tablets, or laptops, an integrated platform that offers accessibility across multiple devices helps address these demands without being physically present.

Here are some front-office manufacturing tasks made possible:

- View current jobs in operation and monitor all applications running

- Determine stock, check inventory, and monitor supplies

- Check and review order status, progress, and delivery

- Real-time supervision of updates

Production Monitoring

Indeed, sustaining production with staffing deficiencies is challenging, especially when it must be done remotely. However, with an effective factory management software, a company can manage staffing accordingly through scheduling systems that enable limited onsite staff without compromising on production targets. Production managers can leverage these smart factory management platforms through:

- Scheduled production staffing times

- Material disposition

- Equipment monitoring

- Addressing maintenance issues in real-time

With real-time production monitoring updates, a company can reduce the need for onsite staff through an integrated factory management software that features manufacturing execution systems or quality control and assurance management tools. Combining these capabilities with the capacity for remote access, production monitoring can easily be managed without disrupting the status quo.

Managing Fluctuating Demand

Another glaring issue that many industries are facing, manufacturing notwithstanding, is meeting the market’s fluctuating demand. Given the unprecedented effects of the pandemic on many nations, the patterns in demand have been shaken, effectively disrupting any previously held forecasts and planning—from expected drop-offs to unexpected spikes in demand.

Integrated ERP platforms offers industry insights that allow companies to plan and adjust accordingly. Manufacturing companies can shift and reallocate resources towards specific products experiencing a rise in demand, such as medical supplies and equipment to support the healthcare industry’s pandemic response. These adjustments come with shifts in operation and production, such as:

- Adaptation of raw materials and supplies

- Changes in schedules, timelines, and processes

- A shift in utilizations of tools

- Reallocation of staff and modifications in workflow

Through an effective ERP platform or integrated production management system in place, these adjustments can be executed and rolled out faster and easier when compared to traditional and manual planning strategies. In the manufacturing industry, time is of the essence, and leveraging these smart factory systems allows rapid responses to a fluctuating demand, mitigating substantial losses.

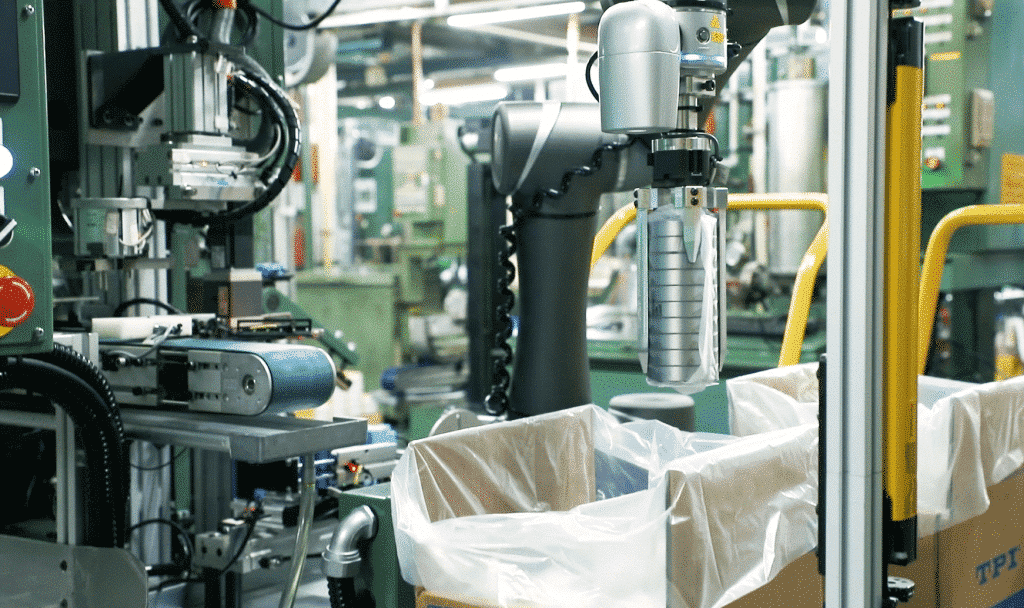

The Smart Factory and the Future of Manufacturing

Should the pandemic be controlled in the near future, the apparent challenges in store for the supply chain and manufacturing industry can include anything from employee reluctance to return to pre-pandemic working setups and processes, shortages in staff and raw supplies, longer lead times, and higher costs to operate. However, the implementation of effective ERP systems can dictate how operations are to continue. Imagine a future in the manufacturing industry centered on seamless production, intelligent factories anchored on big data, efficient supply chains, and increased cobot applications. The Smart Factory is truly the wave of the future.

Don’t hesitate to contact us for more information and visit our blogs for more about smart manufacturing solutions.