In the rapidly evolving landscape of modern manufacturing, collaborative robots, or “cobots,” have emerged as pivotal assets. These advanced machines are designed to work alongside human operators, enhancing productivity, ensuring safety, and offering unparalleled flexibility. As industries grapple with challenges like labor shortages and the demand for agile production systems, cobots present a compelling solution. This article delves into the ascent of cobots in the manufacturing sector, their diverse applications, and the promising future they herald.

The Rise of Cobots in Manufacturing

As manufacturing faces evolving challenges, the integration of collaborative robots (cobots) has emerged as a transformative solution, enhancing efficiency and fostering human-robot synergy.

Addressing Industry Challenges

The manufacturing sector faces mounting pressures: escalating operational costs, a dwindling skilled labor force, and the imperative for adaptable automation solutions. Traditional automation systems, while effective, often lack the flexibility required for today’s dynamic production environments. Cobots bridge this gap by offering:

- Cost Efficiency: Cobots are typically more affordable than traditional industrial robots, both in terms of initial investment and maintenance. Their ease of integration reduces downtime and associated costs.

- Labor Augmentation: With a significant portion of manufacturing positions remaining unfilled, cobots serve as valuable assistants, handling repetitive or hazardous tasks and allowing human workers to focus on more complex responsibilities.

- Flexibility: Designed for quick reprogramming and redeployment, cobots can adapt to various tasks, making them ideal for manufacturers dealing with short production runs or customized products.

Integration into Industry 4.0

The advent of Industry 4.0 has ushered in an era of smart manufacturing, characterized by interconnected systems, real-time data analytics, and enhanced human-machine collaboration. Cobots play a crucial role in this paradigm shift:

- Data-Driven Operations: Equipped with sensors and connectivity features, cobots collect and transmit data, facilitating real-time monitoring and optimization of manufacturing processes.

- Enhanced Collaboration: Advanced safety features allow cobots to operate in close proximity to humans without the need for extensive safety barriers, fostering a collaborative workspace.

- Scalability: As production demands fluctuate, cobots can be easily scaled up or down, ensuring manufacturers remain agile and responsive to market needs.

In essence, the rise of cobots signifies a transformative phase in manufacturing, where human ingenuity and robotic precision converge to create more efficient, safe, and adaptable production environments.

Application of Cobots in Manufacturing

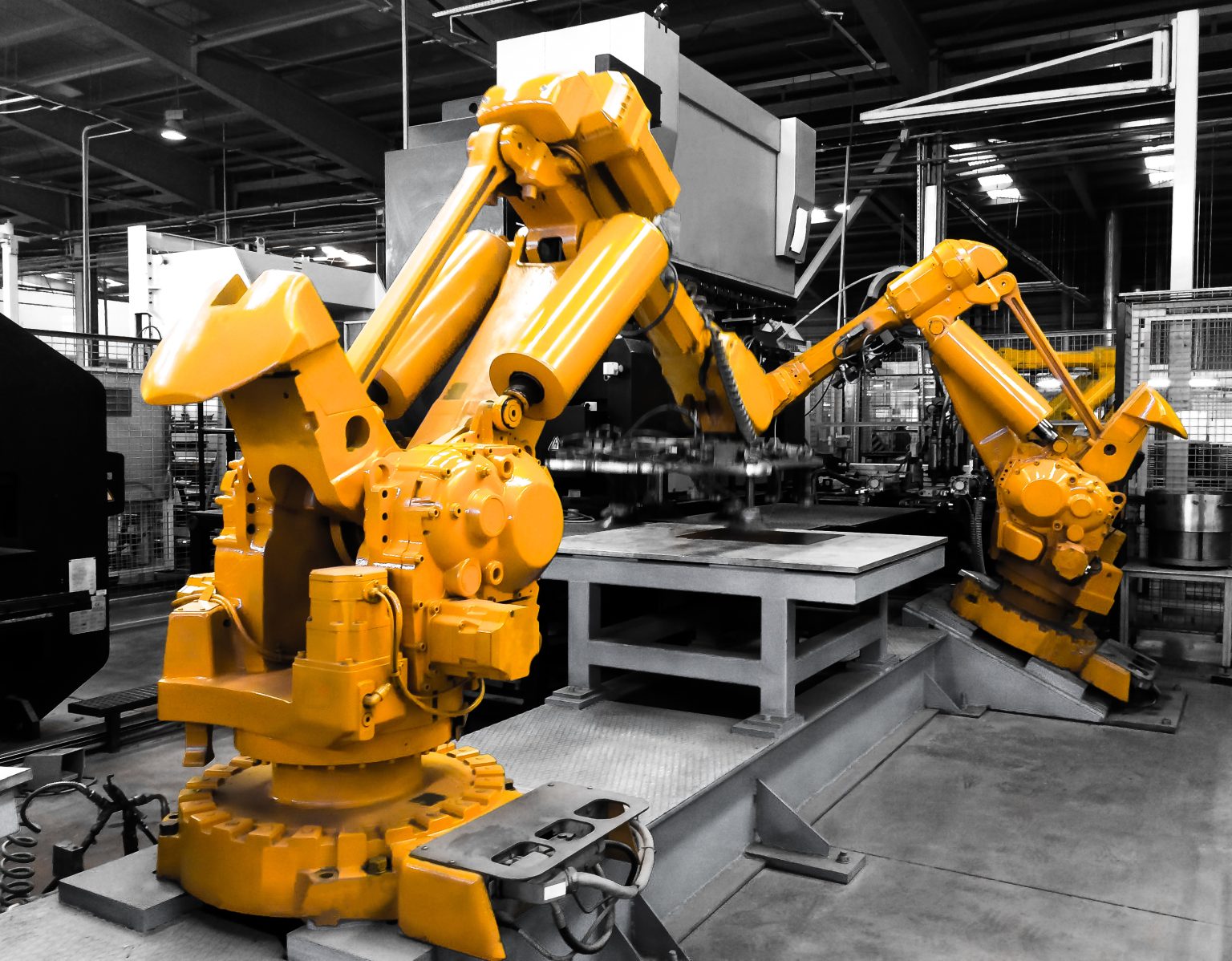

Collaborative robots (cobots) have revolutionized manufacturing by enhancing efficiency, precision, and safety across various operations. Their versatility allows them to seamlessly integrate into multiple stages of the production process. Below are key areas where cobots are making significant impacts:

Picking, Packing, and Palletizing

Common in logistics and warehousing industries, cobots excel in tasks like picking, packing, and palletizing, which are often repetitive and physically demanding. Equipped with advanced vision systems and adaptive grippers, cobots can handle a variety of products, ensuring consistent speed and accuracy. This not only reduces human error but also minimizes the risk of workplace injuries.

Welding

In welding applications, cobots provide unparalleled precision and consistency. They can maintain exact parameters for each weld, reducing defects and ensuring high-quality results. Cobots are particularly beneficial in industries such as automotive, where they are used to weld body panels and chassis components with exacting tolerances. Moreover, cobots enhance safety by handling hazardous tasks, thereby minimizing workers’ exposure to harmful fumes and intense heat.

Assembly

Cobots are adept at performing intricate assembly tasks that require high precision. Their ability to work collaboratively with human operators allows for a harmonious workflow, where cobots handle repetitive tasks while humans focus on more complex aspects. This synergy enhances productivity and product quality. According to research published in ScienceDirect, cobots contribute to increased consistency and speed in assembly processes, leading to improved labor productivity, ultimately improving labor productivity and product quality in industries such as electronics and medical device manufacturing.

Material Handling

Material handling involves the movement of goods within a manufacturing facility, a task well-suited for cobots. They can efficiently transport materials, load and unload machines, and manage inventory, all while reducing the physical strain on human workers.

Material Removal

Tasks such as grinding, deburring, and polishing require consistent force and precision, making them ideal for cobot integration. Cobots can perform these operations with high accuracy, ensuring uniform finishes and reducing the likelihood of defects.

Quality Control

Cobots equipped with advanced sensors and vision systems play a crucial role in quality control. They can conduct inspections, measure components, and detect defects with high accuracy, ensuring that only products meeting quality standards proceed through the production line. This automation of quality assurance processes leads to consistent product quality and reduces the need for rework. Monti Inc. discusses how cobots enhance quality inspection tasks, contributing to overall manufacturing excellence.

The Future of Cobots in Manufacturing

Looking ahead, advancements in artificial intelligence and machine learning are poised to further elevate cobots’ capabilities, solidifying their role in the next era of smart manufacturing.

Market Growth & Adoption Trends

The collaborative robot (cobot) market is experiencing significant growth, driven by the increasing demand for automation and the need for flexible manufacturing solutions. According to a report by Grand View Research, the global cobot market size was valued at USD 2.14 billion in 2024 and is projected to reach USD 11.64 billion by 2030, growing at a compound annual growth rate (CAGR) of 31.6% from 2025 to 2030. This rapid expansion is attributed to the versatility of cobots, which are being adopted across various industries, especially in automotive, electronics, and healthcare, where precision, safety, and production flexibility are critical to success.

The adoption of cobots is not limited to large enterprises; small and medium-sized manufacturers are also integrating cobots into their operations to enhance productivity and maintain competitiveness. The ease of programming and the ability to work safely alongside humans make cobots an attractive option for businesses seeking to automate processes without significant infrastructure changes.

Advancements in AI & Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) technologies is revolutionizing the capabilities of cobots. Modern cobots are equipped with advanced sensors and AI algorithms that enable them to learn from human operators, adapt to new tasks, and improve performance over time. These intelligent systems can detect inefficiencies, optimize workflows, and ensure high precision in complex manufacturing processes.

Furthermore, the development of AI-powered vision systems allows cobots to recognize objects, navigate dynamic environments, and perform quality inspections with greater accuracy. The incorporation of 5G and edge computing technologies facilitates real-time data processing, enabling cobots to respond swiftly to changes on the production floor.

As AI and ML technologies continue to evolve, cobots are expected to become even more autonomous, capable of handling intricate tasks with minimal human intervention. This advancement will not only enhance operational efficiency but also open new avenues for innovation in manufacturing processes.

Invest in a Collaborative Robot for Your Manufacturing Business

Investing in collaborative robots (cobots) offers manufacturers a strategic advantage in today’s competitive landscape. Cobots enhance productivity, ensure safety, and deliver a swift return on investment (ROI), making them an essential component of modern manufacturing operations.

Maximizing Efficiency and ROI

Cobots are designed to work alongside human operators, handling repetitive and physically demanding tasks. This collaboration allows human workers to focus on more complex and value-added activities, thereby increasing overall productivity. Moreover, cobots are known for their quick deployment and ease of programming, which minimizes downtime and accelerates integration into existing workflows.

Financially, cobots present a compelling case. Many manufacturers report achieving ROI in less than a year due to increased throughput and reduced labor costs. Their affordability and scalability make them suitable for businesses of all sizes, from small enterprises to large-scale operations.

Enhancing Workplace Safety and Flexibility

Equipped with advanced sensors and safety features, cobots can safely operate in close proximity to human workers without the need for extensive safety barriers. This not only reduces the risk of workplace injuries but also fosters a more flexible and collaborative work environment. Additionally, cobots can be easily reprogrammed and redeployed for different tasks, providing manufacturers with the agility to adapt to changing production needs.

Cobots Improve Workplace Safety vs. Traditional Industrial Robots

| Features | Cobots | Traditional Industrial Robots |

| Works alongside humans | ✅ Yes | ❌ No (requires barriers) |

| Built-in safety sensors | ✅ Yes | ❌ Typically not included |

| Easy to reprogram | ✅ Yes | ❌ Requires specialists |

| Space-saving setup | ✅ Compact | ❌ Requires dedicated space |

| Suitable for dynamic environments | ✅ Highly adaptable | ❌ Fixed-task setup |

Take the Next Step in Automation

Embracing cobot technology is a forward-thinking move that can significantly enhance your manufacturing capabilities. To explore how cobots can be integrated into your operations and to receive personalized guidance, contact Techman Robot. Our team of experts is ready to assist you in selecting and implementing the right cobot solutions to meet your specific needs.